Retail supply chains are more complex than ever. From global sourcing challenges and tariff fluctuations to shifting consumer expectations, businesses must balance agility with accuracy. In a recent Moxie Retail webinar, industry experts explored how integrating Planning, Product Lifecycle Management (PLM), and Warehouse Management Systems (WMS) creates the backbone of a super-efficient, future-ready retail supply chain.

Why Super Efficiency Matters

The session opened with a simple observation: behind every online purchase lies a maze of interconnected processes. When you order a smartphone online, everything from stock availability to delivery timelines depends on well-orchestrated systems. Yet, many retailers still operate with disconnected tools, leading to errors, delays, and rising costs.

“Super efficiency is what transitions the supply chain to being optimized, accurate, and error free. Ultimately, it’s about saving costs and cutting down time,” said Ameena Kulsum, Senior Manager at Moxie Retail.

Super efficiency, the speakers emphasized, is not just about doing things faster—it’s about building resilient systems that withstand disruptions while keeping customer experience intact.

The Case for Integration

Individually, Planning, PLM, and WMS are powerful. But without integration, they create silos.

- Planning is the digital brain, aligning demand and supply.

- PLM governs product lifecycles from concept to retirement.

- WMS ensures smooth execution across warehousing operations.

When these systems don’t communicate, data moves through email chains or spreadsheets, causing delays and costly errors. As NarsaReddy Aleti, Manager at Moxie, put it:

“Integration is not about IT efficiency—it’s about enabling the business to move forward smarter.”

By connecting these platforms into a digital thread, organizations gain real-time visibility, reduce rework, and respond faster to market shifts.

Key Benefits of Integration

The panel highlighted four transformative outcomes of integration:

- Efficiency – Teams spend less time reconciling data and more time executing.

- Accuracy – Forecasts and product information stay up-to-date, reducing errors.

- Cost Savings – Optimized inventory levels and reduced returns lower expenses.

- Customer Satisfaction – Faster launches and reliable deliveries improve trust.

One analogy from Ameena compared integration to a superhero team-up: “Individually, each system has its powers. But when they come together—like Iron Man and Hulk—they smash challenges.”

Planning: The Digital Brain

Demand planning has evolved from static spreadsheets to AI-powered, predictive systems. Traditional forecasting relied on historical sales data, but modern tools, like o9 Solutions’ MFP platform, harness real-time signals like competitor promotions, weather trends, and social media chatter.

With AI-driven forecasting, businesses can:

- Anticipate demand spikes earlier

- Test “what-if” scenarios for disruptions

- Create agile, scalable strategies

As NarsaReddy noted:

“Planning today is not just about forecasting—it’s about enabling agility and resilience.”

The webinar spotlighted the o9 Solutions platform, which enables scenario planning for tariffs, supplier shutdowns, or regional demand surges. Its enterprise knowledge graph acts like a nervous system, connecting structured and unstructured data into one version of the truth.

PLM: The Strategic Backbone

Product Lifecycle Management (PLM) is more than an IT tool—it’s a strategic backbone. It connects design, sourcing, manufacturing, and logistics into one unified system, ensuring consistency and speed.

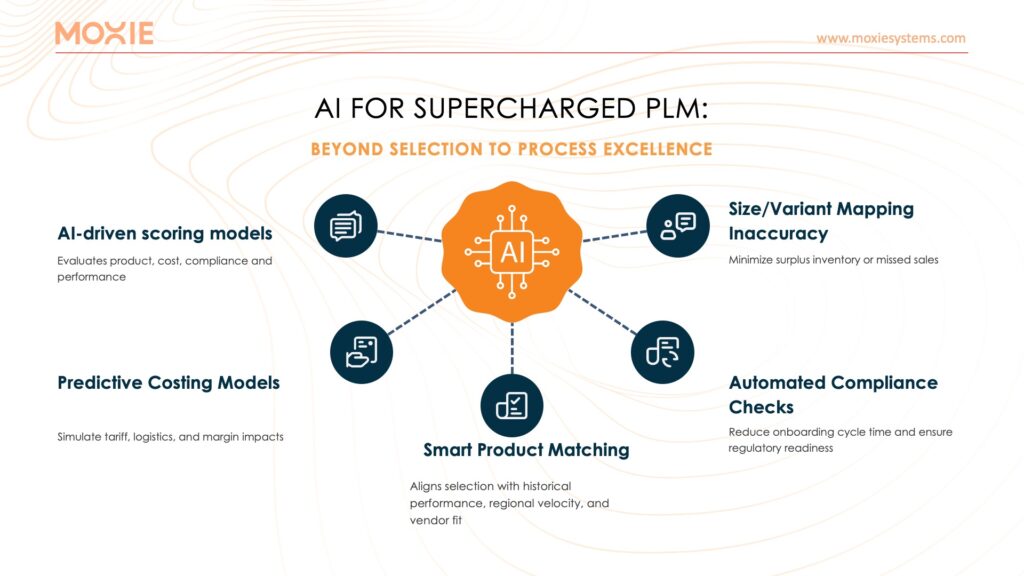

PLM powered by AI enables:

- Supplier scoring models – instantly ranking partners on cost, compliance, and delivery.

- Predictive costing models – simulating tariff or logistics changes in real time.

- Sustainability tracking – embedding certifications and eco-goals directly into workflows.

“PLM is not just managing product data,” said Abhinav Cherukuru, Technical Lead at Moxie, “It ensures all teams move in the same direction, with speed and oversight.”

The team shared a framework—Align, Optimize, Leverage, Measure, Scale—as a repeatable playbook for efficiency gains.

WMS: From Storage to Strategic Hub

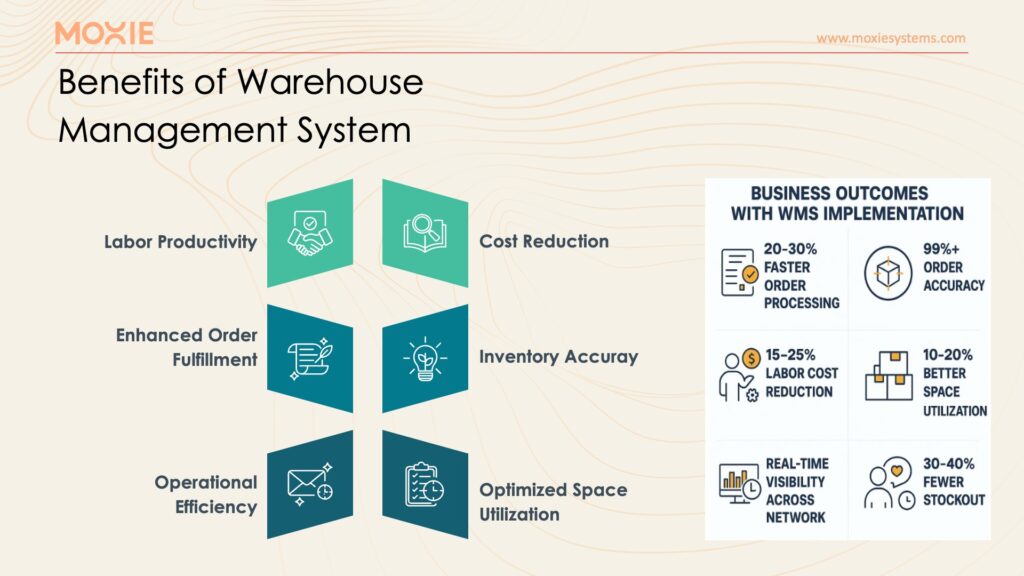

Warehousing has shifted from storage to a central hub of operations. A robust Warehouse Management System (WMS) delivers real-time visibility, automation, and integration across the supply chain.

Key WMS benefits include:

- Cost Reduction through automation and accurate inventory management

- Space Optimization, placing fast-moving items near loading docks

- Labor Productivity via balanced workloads and reduced manual tasks

- Customer Experience, ensuring on-time and error-free fulfillment

One retailer reduced inventory carrying costs by 70% with real-time tracking. Another cut order processing times by 30% using cluster picking and RFID-enabled receiving.

A Real-World Case Study

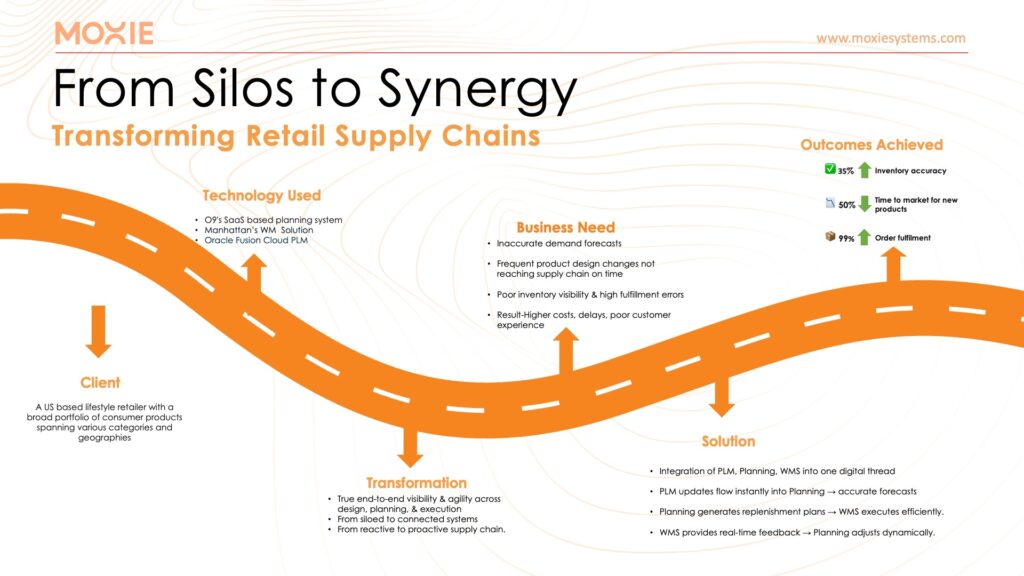

A U.S.-based lifestyle retailer struggling with inaccurate forecasts and fulfillment delays integrated its Planning, PLM, and WMS systems into a single digital thread.

The results were striking:

- 35% improvement in inventory accuracy

- 50% faster time-to-market for new products

- 99% order fulfillment rate

“It wasn’t just a technology upgrade—it was a strategic transformation, turning supply chain into a competitive advantage,” said Suprabha Kolkebail, Senior Engineer at Moxie Retail.

Looking Ahead: Future Trends

The speakers closed with a look toward the future:

- AI in Planning – Simulating scenarios for tariffs, sourcing risks, or demand spikes in real time.

- AI in PLM – Offering design recommendations, material substitutions, and rapid product mockups.

- Omnichannel Fulfillment – WMS connecting seamlessly across online, in-store, and mobile channels.

As retail cycles shorten and consumer expectations rise, these innovations will be key to resilience.

Final Thoughts

This webinar made one thing clear: achieving super efficiency requires more than piecemeal upgrades. By integrating Planning, PLM, and WMS into a single, intelligent ecosystem, retailers can reduce costs, accelerate launches, and delight customers—even in the face of disruption.

Want to see a previous webinar? Check out From Concept to Commerce – A Moxie Retail Webinar